Higher carbon capture potential, lower capital cost, and smaller footprint

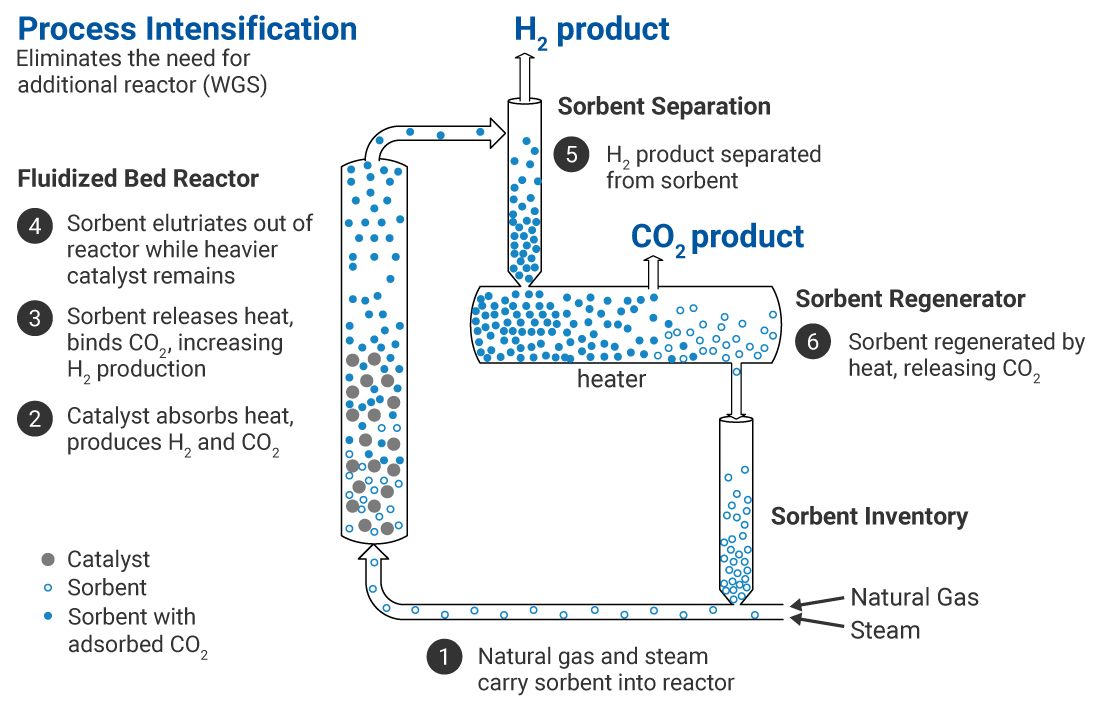

GTI Energy’s hydrogen generator technology offers a highly efficient pathway to produce low carbon hydrogen (H2) with an exceptionally low levelized cost of hydrogen (LCOH). This comes from process intensification which results in a dramatic reduction in CAPEX and OPEX. Based on sorbent enhanced reforming (SER), the process uses chemistry to provide the necessary heat in-situ, instead of external heating. This enables elimination of major equipment and reduction of catalyst volume, creating a much smaller footprint than conventional steam methane reforming (SMR) technology. The use of SER chemistry yields two separate product streams, hydrogen, and CO2, without the need to export steam or incorporate separation equipment. The existing process design enables carbon capture rates greater than 98% while achieving very low carbon intensity when compared to traditional processes, such as SMR with carbon capture or autothermal reforming.

The key economic and performance drivers have been confirmed through studies by independent third parties, including the U.S. Department of Energy (DOE), a major U.S. engineering, procurement, and construction firm, and a major international energy company.

The design is scalable to very large H2 production rates (e.g., 90 MMSCFD [216,000 kg/day]) with the attendant economies of scale, with single or multiple modules.

GTI Energy has completed pilot testing, under DOE funding, which verified catalyst stability and successfully demonstrated SER chemistry and process operation. A large pilot plant (approx. 1 tonne per day hydrogen capacity), at a dedicated site at Cranfield University in the UK is preparing for startup in 2024. Phase 1 of a U.S.-government funded small-scale commercial demonstration plant commenced in 2024 and will be sited at a national location that allows for CO2 sequestration.

Learn More

Contact the energy experts today